From inside (document excerpt):

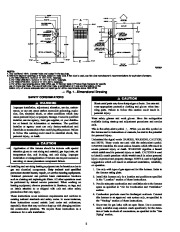

58STA/58STX Induced-Combustion 4-Way Multipoise Furnace Installation, Start-up, Operating, and Service and Maintenance Instructions -Series 100 The 58STA/STX 4-way Multipoise Gas Furnaces feature Carrier’s QuieTech noise reduction system for incredibly quiet induced draft operation. Applications are easy with 4-way multipoise design, through-the-furnace downflow venting, 13 different venting options, and a door designed for easy service access.

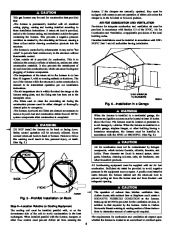

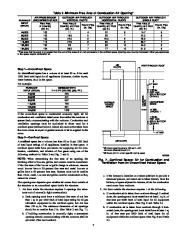

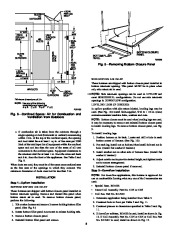

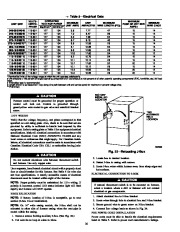

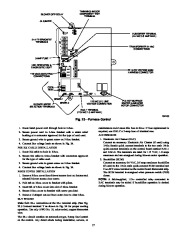

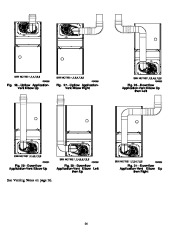

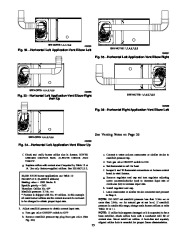

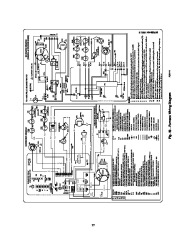

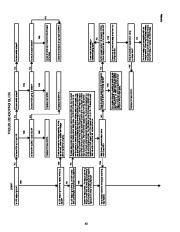

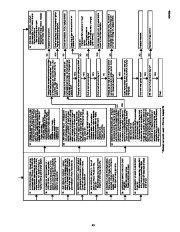

An inner blower door is provided for tighter sealing in sensitive applications. The 58STA/STX furnaces are approved for use with natural or propane gas, and the 58STX is also approved for use in Low NOx Air Quality Management Districts. STANDARD FEATURES – QuieTech noise reduction system – Microprocessor based control center Adjustable heating air temperature rise Adjustable cooling airflow LED diagnostics and self test feature – 4-way Multipoise furnace, 13 vent applications – Inner blower door – Hot surface ignition (HSI) – Draft safeguard switch to ensure proper furnace venting – All models are Chimney-Friendly when used with accessory vent kit – Heat pump compatible – Residential installations eligible for consumer financing through the Retail Credit Program – Twinning in Upflow, Downflow and Horizontal LIMITED WARRANTY – 20-year warranty on “Super STM ” heat exchanger – 5-year parts warranty on all other components Catalog No: 535-80105 Form No. 58ST-11SI 12-02 Single-Stage Induced-Combustion 4-Way Multipoise Furnace Installation, Start-up, Operating, and Service and Maintenance Instructions Series 100/A NOTE: Read the entire instruction manual before starting the installation. This symbol indicates a change since the last issue. TABLE OF CONTENTS SAFETY CONSIDERATIONS .2 INTRODUCTION 4 CODES AND STANDARDS 4 Safety .4 General Installation .4 Combustion and Ventilation Air 4 Duct Systems 5 Acoustical Lining and Fibrous Glass Duct 5 Gas Piping and Gas Pipe Pressure Testing 5 Electrical Connections 5 ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS PROCEDURE 5 LOCATION 5 General 5 Location Relative to Cooling Equipment 6 AIR FOR COMBUSTION AND VENTILATION 6 Unconfined Space .7 Confined Space .7 INSTALLATION .8 Upflow Installation .8 Bottom Return Air Inlet 8 Side Return Air Inlet .8 Leveling Legs (If Desired) 8 Downflow Installation 8 Bottom Return Air Inlet 9 Horizontal Installation 9 Suspended Unit Support 9 Platform Unit Support .9 Roll-Out Protection 9 Bottom Return Air Inlet 9 Side Return Air Inlet .9 Filter Arrangement 9 Air Ducts .9 General Requirements .9 Ductwork Acoustical Treatment .11 Supply Air Connections 12 Return Air Connections .13 Gas Piping .13 Electrical Connections 15 115-V Wiring .16 J-Box Relocation .16 Electrical Connection to J-Box .16 For Power Cord Installation 16 For BX Cable Installation .17 For Power Cord Installation 17 Ca rr ier Cancels: II 310A-45-2/IM-PG8J-02 45-3 / IM-PG8J-03 II 310A- EFFICIENCY RATING CERTIFIED Cor pora ti on CERTIFIED SO 900 E R E D F8 3 1 #A28 REGISTERED QUALITY SYSTEM 24-V Wiring .17 Accessories 17 Venting 18 General Venting Requirements .19 Masonry Chimney Requirements 19 Appliance Application Requirements .21 Additional Venting Requirements .21 Sidewall Venting .21 START-UP, ADJUSTMENT, AND SAFETY CHECK 21 General 21 Start-Up Procedures 23 Adjustments .23 Check Safety Controls 29 Checklist

Carrier Owners Manual - Enlarge page 1 of 45

Carrier Owners Manual - Enlarge page 1 of 45 2 of 45

2 of 45 3 of 45

3 of 45 4 of 45

4 of 45 5 of 45

5 of 45 6 of 45

6 of 45 7 of 45

7 of 45 8 of 45

8 of 45 9 of 45

9 of 45 10 of 45

10 of 45 11 of 45

11 of 45 12 of 45

12 of 45 13 of 45

13 of 45 14 of 45

14 of 45 15 of 45

15 of 45 16 of 45

16 of 45 17 of 45

17 of 45 18 of 45

18 of 45 19 of 45

19 of 45 20 of 45

20 of 45 21 of 45

21 of 45 22 of 45

22 of 45 23 of 45

23 of 45 24 of 45

24 of 45 25 of 45

25 of 45 26 of 45

26 of 45 27 of 45

27 of 45 28 of 45

28 of 45 29 of 45

29 of 45 30 of 45

30 of 45 31 of 45

31 of 45 32 of 45

32 of 45 33 of 45

33 of 45 34 of 45

34 of 45 35 of 45

35 of 45 36 of 45

36 of 45 37 of 45

37 of 45 38 of 45

38 of 45 39 of 45

39 of 45 40 of 45

40 of 45 41 of 45

41 of 45 42 of 45

42 of 45 43 of 45

43 of 45 44 of 45

44 of 45 45 of 45

45 of 45