From inside (document excerpt):

73TC 1993-1995 Room Air Conditioners Start-Up and Service Instructions CONTENTS Page SAFETY REMINDERS . 1 START-UP 1 SERVICE 1,2 General Notes 1 Compressor Replacement . 2 PREVENTIVE MAINTENANCE 2-4 General 2 System Cleaning/Flushing 3 DISASSEMBLY INFORMATION . 5-8 Filter Removal 5 Front Grille Removal 5 Discharge Air Deck Removal 5 Accessing Control Box Components 5 Capacitor Removal . 6 Thermostat Removal 6 Thermostat Bulb Heater Removal (008P Unit Only) 6 Mode Selector Switch Removal 6 Fan Cycle Switch (Energy Saver Switch) Removal (008P Unit Only) .

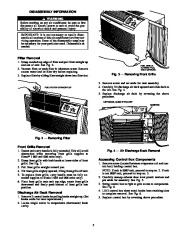

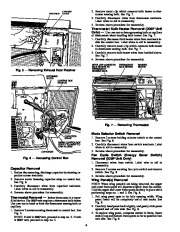

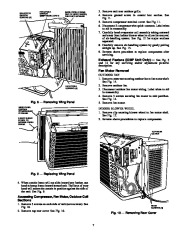

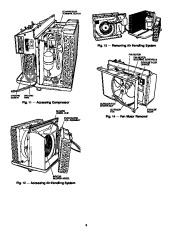

6 Wing Panel(s) Removal . 6 Accessing Compressor, Fan Motor, Outdoor Coil Sections . 7 Exhaust Feature (008P Unit Only) 7 Fan Motor Removal . 7 · OUTDOOR FAN · INDOOR BLOWER WHEEL SERVICE POINTS . 9 TROUBLESHOOTING 10 START-UP Refer to operating instructions in Owner’s Guide provided with room air conditioner. Refer to Table 1 for specific model number information to properly service, maintain, and disassemble the unit. SERVICE General Notes — These Start-Up and Service Instructions are provided to assist the trained and qualified service technician in repairing or replacing components of Carrier room air conditioner model offerings for 1993-1995. Room air-conditioning models are cooling-only units. These instructions contain disassembly photos for Model 73TC (Siesta I and Siesta II). A typical 73TC unit is shown in Fig. 1. Unit physical data is found in Tables 2-8. COO LER Fig. 1 — Model 008P IMPORTANT: Repairing and servicing air conditioners can be hazardous for untrained individuals. The instructions printed in this publication are for properly trained and qualified Carrier service technicians only. SAFETY REMINDERS 1. Carry a fire extinguisher in your truck. Keep it within reach when using a torch. Check fire extinguisher periodically to be sure it is fully loaded and functional. 2. Know how to handle oxyacetylene equipment safely. Lock the equipment in an upright position in the truck and at the job site. 3. Use dry nitrogen or carbon dioxide to pressurize the system for leak checking. Always use a good regulator. Be careful not to exceed 150 psig test pressure in the hermetic compressor. 4. Wear safety goggles and gloves when recovering refrigerant from a system. 5. Attend shop safety meetings. Before working on any air conditioner, be sure to first disconnect all electric power to the unit to avoid the possibility of electrical shock and personal injury. Before disconnecting, discharge capacitors by shorting capacitors across terminals. Shield coils with cardboard to protect hands against injury from sharp metal edges when removing compressor and other components. When disassembling wiring, use numbered stickers to identify wire leads and terminals. This aids in quick, accurate reassembly. Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Carrier Owners Manual - Enlarge page 1 of 12

Carrier Owners Manual - Enlarge page 1 of 12 2 of 12

2 of 12 3 of 12

3 of 12 4 of 12

4 of 12 5 of 12

5 of 12 6 of 12

6 of 12 7 of 12

7 of 12 8 of 12

8 of 12 9 of 12

9 of 12 10 of 12

10 of 12 11 of 12

11 of 12 12 of 12

12 of 12