From inside (document excerpt):

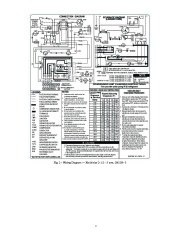

25HBS3 Baset Series Heat Pump with Puronr Refrigerant 1 1/2 To 5 Nominal Tons Wiring Diagrams CONNECTION DIAGRAM *CHS BLK or RED RED or BLK L1 L2 EQUIP

ACCELERATED TO 21 SEC. 60 MIN. ACCELERATED TO 14 SEC. 30 MIN. ACCELERATED TO 7 SEC. DEFROST CYCLE: 10 MIN. ACCELERATED TO 2 SEC. INDOOR UNIT TERMINAL BLOCK CONDENSING UNIT CHARGING INSTRUCTIONS For use with units using R-22 refrigerant REQUIRED LIQUID LINE TEMPERATURE Liquid (PSIG) Required Subcooling Pressure Temperature (ºF) at Service Valve 104 COOLING ONLY CHARGING PROCEDURE 1. Only use sub cooling charging method when OD ambient is greater than 70ºF and less than 100ºF, indoor temp is greater than 70ºF and less than 80ºF, and line set is less than 80 ft. 2. Operate unit a minimum of 15 minutes before checking the charge. 3. Measure liquid service valve pressure by attaching an accurate gauge to the service port. 4. Measure the liquid line temperature by attaching an accurate thermistor type or electronic thermometer to the liquid line near the outdoor coil. 5. Refer to unit rating plate for required subcooling temperature. 6. Find the point where the required subcooling temperature intersects the measured liquid service valve pressure. 7. To obtain the required subcooling temperature at specific liquid line pressure, add refrigerant if liquid line temperature is higher than indicated. When adding refrigerant, charge in liquid form using a flow restricting device into suction service port. Recover refrigerant if temperature is lower. Allow a tolerance of +/- 3ºF. G INDOOR THERMOSTAT (NOTE #5)

Carrier Owners Manual - 1 of 4

Carrier Owners Manual - 1 of 4 Carrier Owners Manual - 2 of 4

Carrier Owners Manual - 2 of 4 Carrier Owners Manual - 3 of 4

Carrier Owners Manual - 3 of 4 Carrier Owners Manual - 4 of 4

Carrier Owners Manual - 4 of 4